Product Introduction:

1. Reducing raw material moisture, lower drying cost

2. It is suitable for low, medium and high plastic raw material

3.It is suitable for one and twice stacking ,therefore simplying production chart, saving investment

4.Finished product with higher density and higher strenger,not easy to be damaged while packing ,transporting and construction.

Product Parts:

Alloy brick mould |

Alloy hollow brick mould |

Alloy mixer blades |

Auger |

Thrust bearing |

Reducer |

Auger adopts high chromium raw materials,the auger front part can produce 20 million bricks,the auger back part can produce 40 million bricks one time. | High load capacity to admit any pressure from soft to stiff extrusion condition. | Reducers with parallel shafts,case hardened and ground helical gears to ensure secure,progressive transmission and quiet operation and long durability. |

| |

Extruder shaft | Liner |

Extruder shaft and gear adopts heat treatment.If with proper maintenance,we can give at least 3 years guarantee for gears and shaft. | 1.Hinged body.Easy opening for maintenance tasks and part replacement 2.Highly wear resistant chrome alloy liners with a bolt-free system,preventing air leaks and making replacement operations easier. |

Clay Brick Sample:

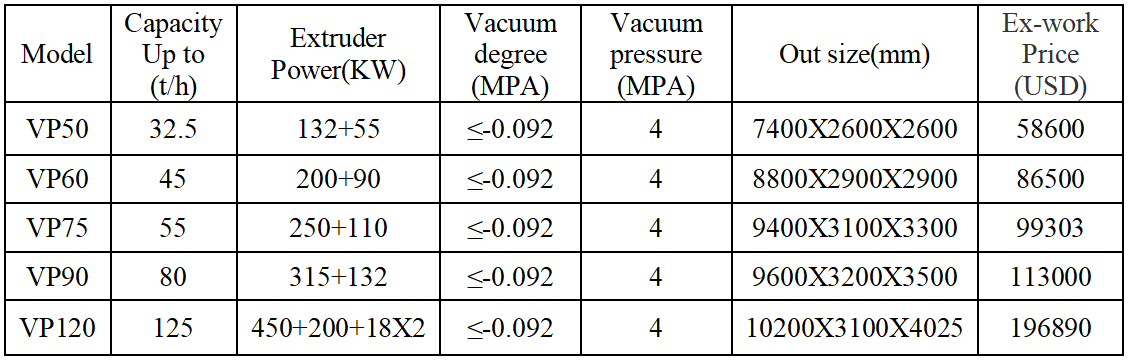

Technical Parameters: