Product Introduction:

1. Strong applicability, lower energy consumption, only use one motor.

2. The raw material for making bricks can be clay, coal gangue.

3. It can produce solid,multi-holes and hollow bricks.

Product Parts:

Alloy brick mould |

Alloy hollow brick mould |

Alloy mixer blades |

Auger | Thrust bearing |

Reducer |

Auger adopts high chromium raw materials,the auger front part can produce 20 million bricks,the auger back part can produce 40 million bricks one time. | High load capacity to admit any pressure from soft to stiff extrusion condition. | Reducers with parallel shafts,case hardened and ground helical gears to ensure secure,progressive transmission and quiet operation and long durability. |

| Different types of augers are available to adapt for varying clay requirements and shaping conditions: 1. Highly wear resistant chromium alloy 2. Steel alloys with chromium or tungsten carbides resurfacing 3. Steel alloy The whole Magnabloc extruder range offers alternatives for cylindrical,conical or extra-conical auger configurations to better adapt for any product need,type of clay and shaping requirements. |

Clay brick sample:

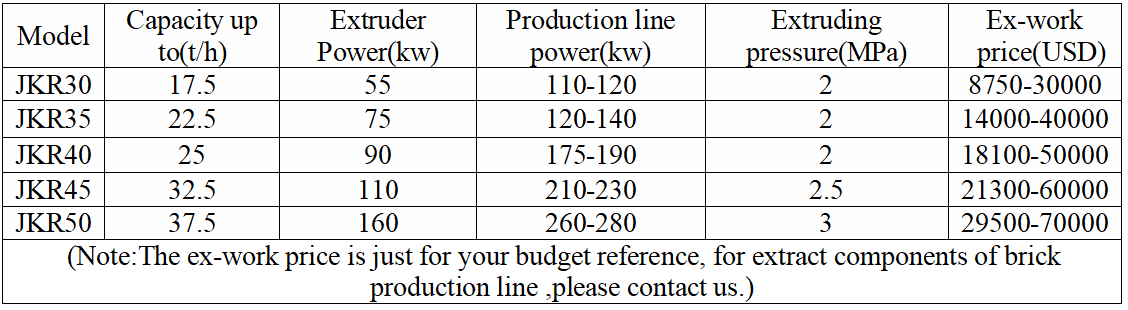

Technical Parameters:

LangPu JKR45 clay brick production line

LangPu jkr40 automatic brick making machine

LangPu JKR30 red fired mud clay brick making machine