(1)Controlled by PLC system;

(2)Material stock hopper and the material feeding hopper separated,quantitative feed of materials achieved, which effectively avoid the liquefaction of concrete and reduce the feeding time;

(3)Feeding system adopt the multi-stirring fork, the mold case can slosh before and after quickly, in order to put the materials full the bottom of the mold case fast;

(4)Effectively guarantee the reliability and stability of machine long-term work,reducing the maintenance failure rate;

(5)Wide applicability.This machine can produce different kinds of standard block,standard brick, planting brick, revetment ties, pavement slabs, decorative brick and so on

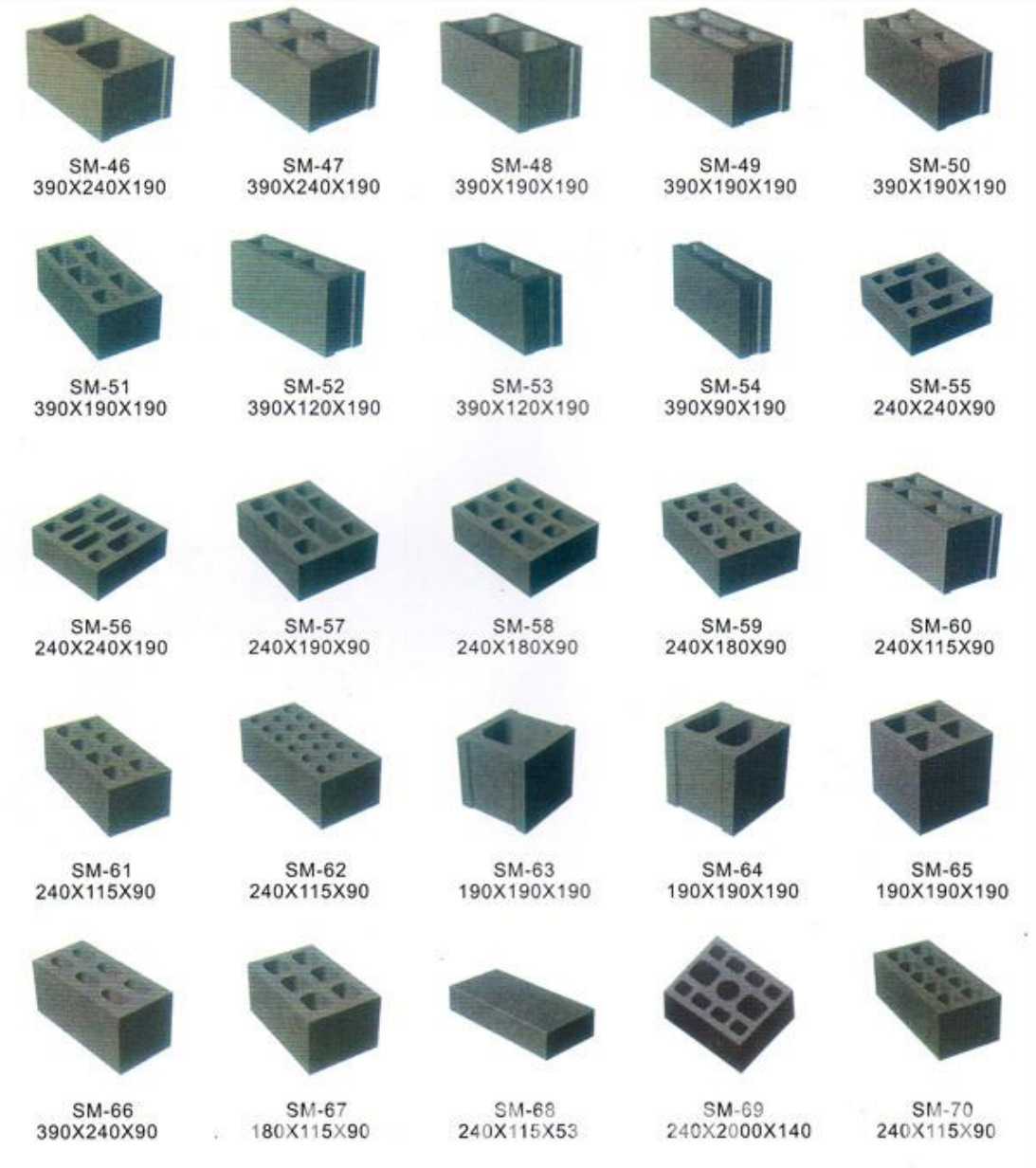

Brick Sample:

Introduction & specification of QT 5-15 | |

Item | Specifications |

Vibration | Strong Pressure Vibration (Hydraulic Transmission) |

Rating Pressure | 20 Mpa |

Vibration Frequency | 2800-4800 times/min |

Molding Cycle | 12-18 sec. /time |

Pallet Size (Bamboo Pallet) | 1100×550×30 mm |

Pallet Size (PVC Pallet) | 1100×550×18 mm |

Raw Materials | Crushed stone, sand, cement, dust and coal fly ash, cinder, slag gangue, gravel, perlite and other industrial wastes. |

Operating Workers Required | Five to Seven Ones |

Field Areas Required | 4000-6000 ㎡ |

Capacity(pcs/h) | 1200 |

Related Product:

No. | Model | Pcs/cycle | Capacity(pcs/h) | Pcs/8hours | Automation | Price Scope /USD |

1 | QTJ4-15 | 4 | 960 | 7680 | Semi/full auto | 14000~16000 |

2 | QTJ5-15 | 5 | 1200 | 9600 | Full auto | 14000~16000 |

3 | QTJ6-15 | 6 | 1440 | 11520 | Full auto | 20000~22000 |

4 | QTJ8-15 | 8 | 1920 | 15360 | Full auto | 21000~23000 |

5 | QTJ10-15 | 10 | 2400 | 19200 | Full auto | 26000~28000 |

6 | QTJ12-15 | 12 | 2880 | 23040 | Full auto | 29000~31000 |

Note: The above price scope is only for main machine without including material batching system | ||||||