QTJ4-30 changes double shafts into four shafts and being coated with hard cadmium.So,it is good in stability and perfect in wearing capacity.Using a larger vibrating box,the blocks are produced with vertical vibration with good compressive stress and high density.It’s an ideal model for small and medium sized investors.

QTJ4-30A | The machine press up and down then take out the block,button control, no brick platform and manual material feeding system. |

QTJ4-30B | Compared with QTJ4-30A,this machine have brick platform,controled by Electronic control cabinet,Manual Pushing-Pulling mould mounting system and also manual material feeding system. |

QTJ4-30C | Compared with QTJ4-30B,this machine with auto material feeding system and auto material feeding system. |

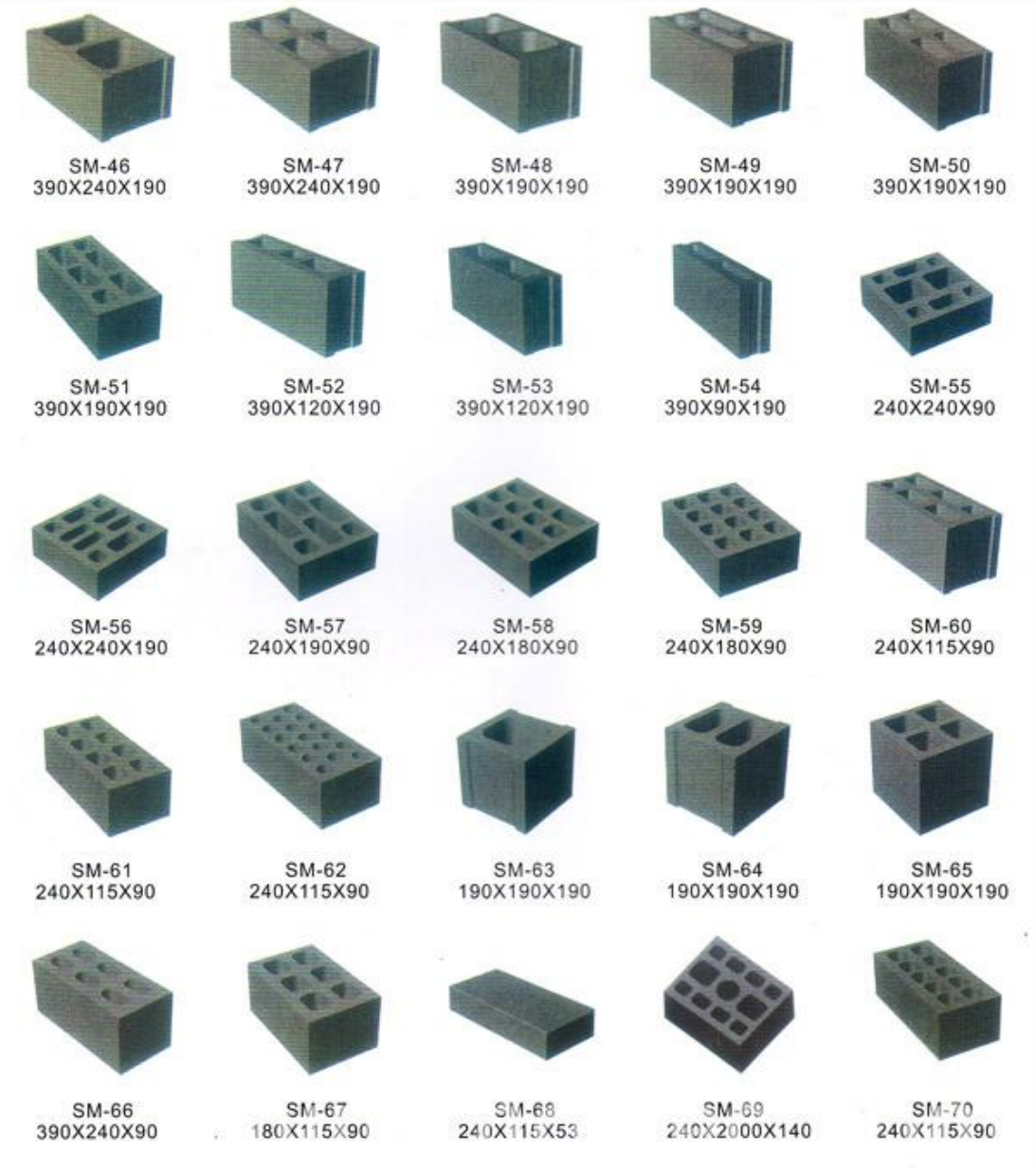

Brick Sample:

Technical Parameters:

Introduction & specification of QTJ 4-30 | |

Product Capacity Per Mould | 400*200*200 4pcs/mould hollow brick |

390*240*190 3pcs/mould hollow brick | |

240*115*53 26pcs/mould standard brick | |

Total Weight | 3.0T |

Forming Cycle | 30-35s |

Power | 13kw |

Size of host Machine | 3600*1700*2650mm |

Size of Carriage Plate | 850*550*30mm |

Daily production capacity for hollow bricks | 3000pcs |

Daily production capacity for standard bricks | 18000pcs |

Related Product:

No. | Model | Capacity(pcs/h) | Driving force | Phase | Automation | Price Scope |

1 | QTJ4-30A | 480 | mechanical | Three | Semi-auto | 2700~2900 |

2 | QTJ4-30B | 554 | mechanical | Three | Semi-auto | 3600~3900 |

3 | QTJ4-30C | 554 | mechanical | Three | Semi-auto | 4100~4300 |

Note: The above price scope is just for your budget reference based on standard 400X200X200 mould , the exact offer will be sent once you confirm the model and mould | ||||||